Stonemasonry is an ancient craft that has shaped our built environment for thousands of years. This article delves into the intricate details of the tools used in heritage and restoration stonemasonry, providing a comprehensive understanding of their history, usage, and significance in the preservation of our architectural heritage.

From the simplest hand tools to the most sophisticated machinery, stonemasonry tools have evolved over time, reflecting the technological advancements of each era. Yet, the fundamental principles of working with stone remain the same, demanding a deep understanding of the material and a high level of skill and precision.

History of Stonemasonry Tools

The history of stonemasonry tools is as old as civilization itself. The earliest stone tools, dating back to the Stone Age, were simple and rudimentary, used for cutting, scraping, and shaping stone. As civilizations advanced, so did the complexity and efficiency of these tools.

During the Middle Ages, the craft of stonemasonry reached its zenith, with the construction of grand cathedrals and castles. The tools used during this period were predominantly hand tools, crafted by the masons themselves. These included chisels, mallets, and trowels, which remain essential tools in modern stonemasonry.

Evolution of Tools

The Industrial Revolution in the 18th century brought about significant changes in stonemasonry tools. The introduction of steam power led to the development of powered saws and drills, greatly increasing the speed and efficiency of stone cutting and shaping. However, these machines were large and stationary, limiting their use to quarries and workshops.

In the 20th century, the advent of electricity and portable power tools revolutionized stonemasonry. Electric saws, drills, and grinders allowed for more precise and efficient work, expanding the possibilities of stone design and construction. Despite these advancements, traditional hand tools continue to be used, particularly in heritage and restoration work, where the aim is to preserve the original craftsmanship and character of the stone.

Impact on Stonemasonry Practice

The evolution of stonemasonry tools has had a profound impact on the practice of the craft. The increased efficiency and precision of modern tools have allowed for more complex and intricate stone designs, pushing the boundaries of what is possible in stone construction.

However, the reliance on machinery has also led to a decline in traditional stonemasonry skills. The hand-eye coordination, precision, and patience required to shape stone with hand tools are skills that are becoming increasingly rare. This has implications for the preservation of historic stone buildings, as these skills are often needed to accurately replicate original stone details.

Types of Stonemasonry Tools

Stonemasonry tools can be broadly categorized into hand tools and power tools. Hand tools are the most basic and essential tools in stonemasonry, used for cutting, shaping, and finishing stone. Power tools, on the other hand, are used for more heavy-duty tasks such as drilling, sawing, and grinding.

Each tool has a specific purpose and is designed to work with the unique properties of stone. The choice of tool depends on the type of stone, the desired finish, and the specific task at hand.

Hand Tools

Hand tools are the most traditional and fundamental tools in stonemasonry. They include chisels, mallets, trowels, and hammers. Chisels are used for cutting and shaping stone, with different types of chisels used for different types of cuts. Mallets are used to strike the chisel, providing the force needed to cut the stone. Trowels are used for applying mortar, while hammers are used for breaking stone and driving chisels.

Despite the advent of power tools, hand tools continue to be used in stonemasonry, particularly in heritage and restoration work. The use of hand tools allows for a greater level of control and precision, enabling the mason to replicate the original craftsmanship and character of the stone.

Power Tools

Power tools have greatly increased the speed and efficiency of stonemasonry work. They include electric saws, drills, and grinders. Electric saws are used for cutting large pieces of stone, while drills are used for making holes in stone. Grinders are used for smoothing and polishing stone surfaces.

While power tools have made stonemasonry work more efficient, they also require a high level of skill and experience to use safely and effectively. Improper use of power tools can result in damage to the stone and injury to the mason.

Tool Maintenance and Safety

Maintaining stonemasonry tools is essential for their longevity and performance. Regular cleaning, sharpening, and proper storage can greatly extend the life of these tools. Similarly, safety is paramount in stonemasonry. The use of protective equipment, safe handling practices, and regular tool maintenance can prevent accidents and injuries.

Whether using hand tools or power tools, proper training and experience are essential in stonemasonry. The craft requires a deep understanding of the material, the tools, and the techniques, making it a highly skilled and demanding profession.

Maintenance Practices

Regular maintenance of stonemasonry tools is essential to keep them in good working condition. This includes cleaning the tools after each use to remove any stone dust or debris, which can cause the tools to become dull or damaged. Sharpening the tools is also important, particularly for cutting tools such as chisels and saw blades. A sharp tool not only performs better but is also safer to use.

Proper storage of tools is another important aspect of tool maintenance. Tools should be stored in a dry, clean environment to prevent rust and damage. They should also be organized in a way that allows for easy access and prevents accidental damage.

Safety Measures

Safety is paramount in stonemasonry. The use of protective equipment, such as safety glasses, gloves, and steel-toed boots, is essential to protect against injuries. Safe handling practices, such as using the right tool for the job, maintaining a safe working distance, and keeping the work area clean and free of tripping hazards, can also prevent accidents.

Furthermore, regular tool maintenance is an important part of safety in stonemasonry. A well-maintained tool is less likely to break or malfunction, reducing the risk of injury. Regular inspections of power tools, including checking for damaged cords and loose parts, can also prevent accidents.

Role of Tools in Heritage and Restoration Stonemasonry

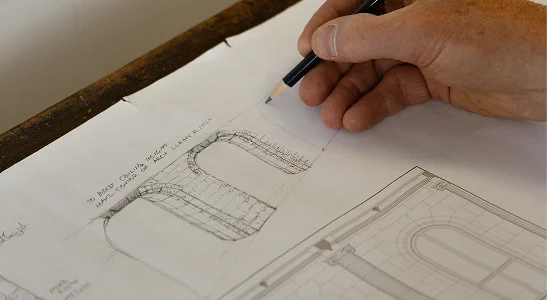

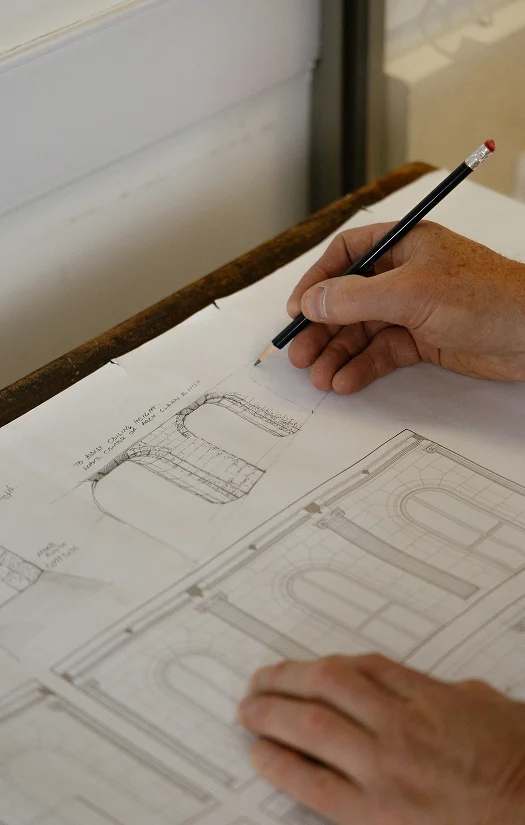

In heritage and restoration stonemasonry, the role of tools is not just functional but also historical. The tools used in this field are often the same as those used by the original masons, providing a tangible link to the past. These tools allow the mason to replicate the original craftsmanship and character of the stone, preserving the architectural heritage for future generations.

The use of traditional hand tools is particularly important in heritage and restoration work. These tools allow for a greater level of control and precision, enabling the mason to accurately replicate original stone details. The use of power tools, while efficient, can often result in a loss of historical accuracy and character.

Replicating Historic Techniques

The use of traditional tools and techniques is essential in replicating the original craftsmanship of historic stone buildings. This involves a deep understanding of the original masonry techniques, as well as the ability to use the same tools and materials. The goal is to preserve the original character and integrity of the stone, rather than simply repairing or replacing it.

This approach requires a high level of skill and experience, as well as a deep respect for the historical significance of the stone. It is a labor-intensive process, often requiring more time and effort than modern masonry techniques. However, the result is a faithful restoration that preserves the architectural heritage for future generations.

Challenges and Solutions

Heritage and restoration stonemasonry presents a number of challenges, particularly when it comes to matching the original stone and mortar. The availability of original materials can be limited, and the techniques used to work these materials may have been lost over time. In these cases, the mason must use their skill and creativity to find suitable alternatives that maintain the historical accuracy and character of the building.

Another challenge is the use of modern tools and materials, which can often result in a loss of historical accuracy. The use of traditional hand tools and techniques can help to overcome this challenge, providing a more authentic restoration. However, this approach requires a high level of skill and experience, as well as a deep understanding of the original masonry techniques.

Conclusion

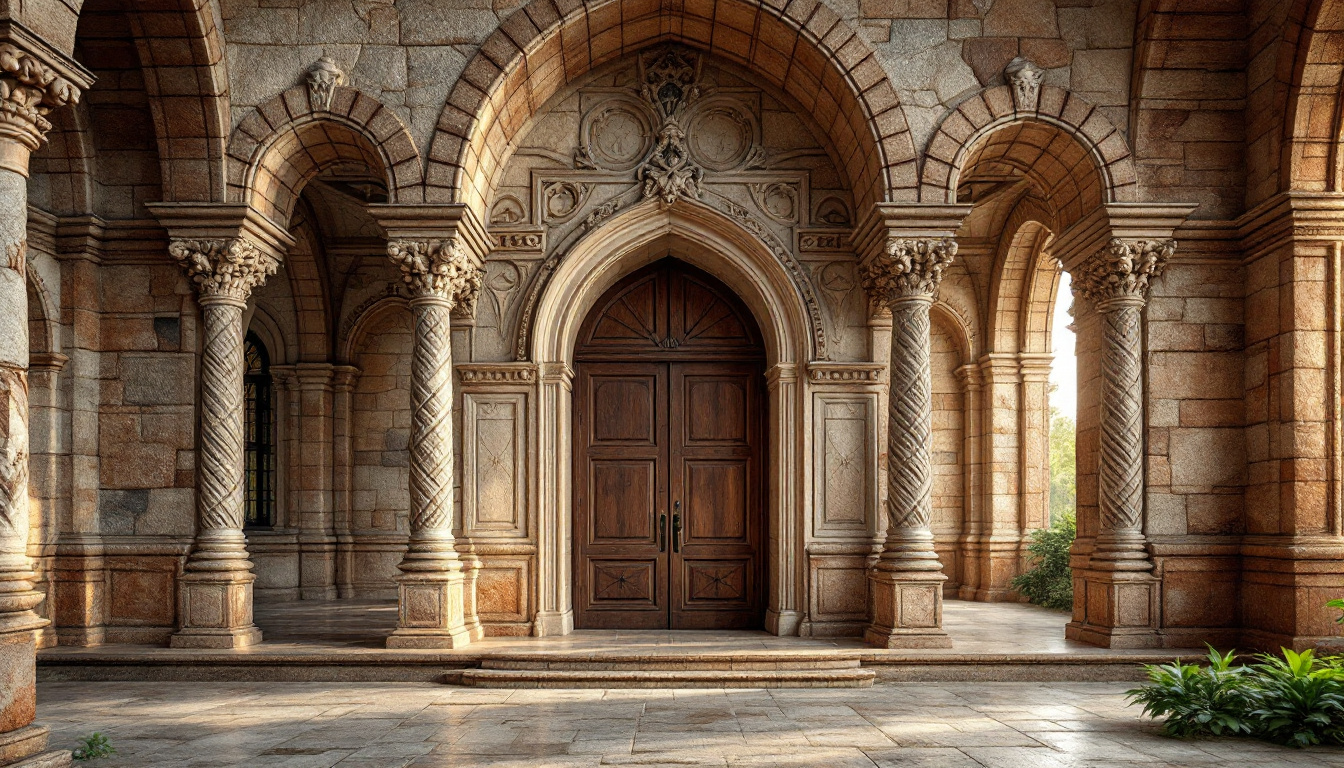

Stonemasonry tools play a crucial role in the preservation of our architectural heritage. From the simplest hand tools to the most sophisticated machinery, these tools allow us to shape and manipulate stone, creating structures that stand the test of time. As we continue to advance technologically, it is important to remember the value of traditional tools and techniques, particularly in the field of heritage and restoration stonemasonry.

Whether you are a professional stonemason, a student of architecture, or simply a lover of historic buildings, understanding the tools of stonemasonry can provide a deeper appreciation of this ancient craft. It is through this understanding that we can continue to preserve and celebrate our architectural heritage, ensuring its survival for future generations.

Discover the Craftsmanship of A F Jones Stonemasons

If you’re inspired by the enduring beauty of stonemasonry and wish to incorporate this heritage craft into your next project, A F Jones Stonemasons is here to guide you from concept to completion. With over 160 years of expertise, we blend traditional skills with cutting-edge technology to realize the true potential of stone in your buildings. Our dedicated team is ready to tackle projects of any scale, from grand architectural endeavors to bespoke private commissions. Visit our showroom in the rolling hills of Oxfordshire, or make an enquiry today to explore how we can bring precision, efficiency, and timeless elegance to your space.