Mortar, a fundamental component in the field of stonemasonry, has a rich heritage and plays a crucial role in the restoration of historical structures. This article delves into the intricate details of mortar, its historical significance, and its application in restoration stonemasonry.

Understanding the nuances of mortar is not just about knowing its composition or application techniques. It’s about appreciating its role in shaping human civilization, preserving our architectural heritage, and ensuring the longevity of our built environment. Let’s embark on this journey of exploration.

Historical Overview of Mortar

Mortar has been a cornerstone of construction since ancient times. The earliest evidence of its use dates back to 6000 BC, in what is now modern-day Turkey. The ancient Egyptians also used a form of gypsum mortar in the construction of their pyramids, demonstrating the material’s durability and longevity.

The Romans, known for their architectural prowess, made significant advancements in mortar technology. They discovered that adding volcanic ash to the mix resulted in a substance that could set under water, leading to the development of hydraulic mortar. This was a monumental discovery that revolutionized construction, particularly in the building of aqueducts and harbors.

The Middle Ages and Mortar

During the Middle Ages, the use of mortar continued to evolve. Lime mortar, made from burnt limestone and sand, became the standard. This type of mortar was used extensively in the construction of castles, cathedrals, and other significant structures of the period. The strength and durability of lime mortar contributed to the longevity of these structures, many of which still stand today.

Despite the widespread use of lime mortar during this period, the knowledge and techniques of its production were often closely guarded secrets. This resulted in regional variations in the quality and characteristics of the mortar, which can be seen in the different styles and durability of structures across Europe.

The Industrial Revolution and Mortar

The Industrial Revolution brought about significant changes in the production and use of mortar. The invention of Portland cement in the early 19th century marked a major shift. This new type of cement, made from heated limestone and clay, was stronger and faster-setting than traditional lime mortar.

However, the widespread use of Portland cement also had its drawbacks. Its rigidity and lack of breathability can cause damage to older buildings, particularly those built with softer, more porous materials. This has led to a resurgence in the use of traditional lime mortar in the restoration of historic buildings.

The Composition of Mortar

Mortar is a mixture of a binder, aggregate, and water. The binder, typically cement or lime, gives the mortar its strength and durability. The aggregate, usually sand, provides bulk and helps to control the mortar’s workability and setting time. Water is needed to activate the binder and to make the mixture workable.

The specific proportions of these components can vary depending on the desired properties of the mortar. For example, a higher proportion of binder will result in a stronger, but less workable, mortar. Conversely, a higher proportion of aggregate will result in a more workable, but weaker, mortar.

Types of Binders

The type of binder used in mortar can greatly affect its properties. Lime, cement, and a combination of the two are the most common binders used today. Lime mortar, made from burnt limestone, is soft and breathable, making it ideal for use in older buildings. Cement mortar, made from Portland cement, is stronger and faster-setting, making it suitable for modern construction.

Hydraulic lime, a type of lime that sets through hydration, is also used in some types of mortar. This binder offers a compromise between the softness and breathability of traditional lime mortar and the strength and speed of setting of cement mortar.

Types of Aggregate

The type of aggregate used in mortar also plays a significant role in its properties. The most common type of aggregate is sand, but other materials, such as crushed stone or recycled concrete, can also be used. The size, shape, and hardness of the aggregate particles can affect the workability, strength, and durability of the mortar.

The choice of aggregate can also have aesthetic implications. For example, the color and texture of the sand used can affect the appearance of the finished mortar. This is particularly important in restoration stonemasonry, where the goal is often to match the original appearance of the building as closely as possible.

Application Techniques

The application of mortar is a skilled task that requires knowledge, experience, and precision. The process involves spreading the mortar onto the surfaces of the stones or bricks, positioning them, and then filling the gaps (or joints) between them. The mortar must be applied evenly and in the correct quantity to ensure a strong and durable bond.

There are various techniques for applying mortar, each with its own advantages and challenges. The most common method is troweling, where the mortar is spread onto the stone or brick with a flat tool called a trowel. Other methods include pointing, where the mortar is pushed into the joints after the stones or bricks have been laid, and grouting, where the mortar is poured or pumped into the joints.

Pointing Techniques

Pointing is a crucial part of the mortaring process, particularly in restoration stonemasonry. It involves filling the joints between the stones or bricks with mortar and then shaping it to create a finished appearance. There are several different styles of pointing, each with its own aesthetic and practical implications.

Flush pointing is the simplest style, where the mortar is finished flush with the surface of the stones or bricks. Recessed pointing involves setting the mortar back from the surface, creating a shadow effect. Raised pointing, where the mortar protrudes from the surface, is less common but can be used to create a distinctive appearance. The choice of pointing style can greatly affect the appearance of the finished masonry, and should be chosen with care.

Grouting Techniques

Grouting is another important aspect of the mortaring process. It involves filling the voids within and between the stones or bricks with a fluid form of mortar. This can be done by pouring the grout into the joints, or by using a grout pump to inject it under pressure.

The choice of grouting technique can depend on a number of factors, including the size and shape of the joints, the type of mortar used, and the desired appearance of the finished masonry. Regardless of the technique used, it is crucial to ensure that the grout fully fills the joints and voids, as any gaps can compromise the strength and durability of the masonry.

Restoration Stonemasonry

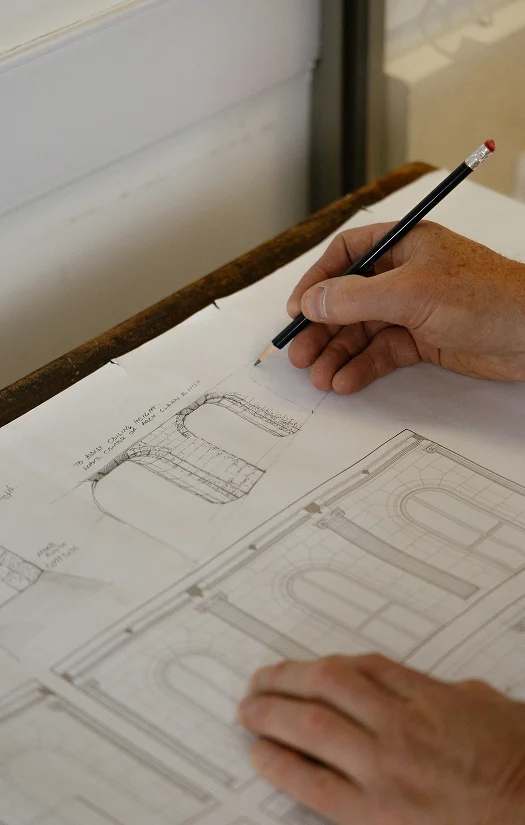

Restoration stonemasonry is a specialized field that involves the repair and conservation of historic buildings. This often involves the use of traditional materials and techniques, including the use of mortar. The goal is to preserve the original character of the building while ensuring its structural integrity and longevity.

One of the key challenges in restoration stonemasonry is matching the original materials and techniques as closely as possible. This often involves detailed analysis of the original mortar, including its composition, texture, and color. The new mortar must then be formulated to match these properties as closely as possible.

Challenges of Restoration

Restoration stonemasonry presents a number of unique challenges. One of the most significant is the need to work with a wide range of materials and conditions. The stones or bricks may be of different types, sizes, and ages, and may be in various states of decay. The mortar may also have deteriorated over time, requiring careful removal and replacement.

Another challenge is the need to balance preservation with practicality. While the goal is to preserve the original character of the building, it is also necessary to ensure its structural integrity and functionality. This often involves making difficult decisions about which features to preserve, which to repair, and which to replace.

Techniques of Restoration

There are various techniques used in restoration stonemasonry, many of which involve the use of mortar. These include repointing, where the old mortar is removed and replaced with new mortar; consolidation, where a weak or decayed stone is strengthened with a mortar or grout; and replacement, where a damaged stone is removed and replaced with a new one.

Each of these techniques requires a high level of skill and expertise, as well as a deep understanding of the properties and behavior of mortar. The choice of technique can depend on a number of factors, including the condition of the stones or bricks, the type and condition of the original mortar, and the desired appearance of the finished masonry.

Conclusion

Mortar is more than just a binding agent. It is a material that has shaped our built environment for thousands of years, and continues to do so today. Its role in restoration stonemasonry is particularly significant, as it allows us to preserve our architectural heritage for future generations.

Understanding the history, composition, and application techniques of mortar is crucial for anyone involved in stonemasonry, particularly in the field of restoration. It is a complex and fascinating subject, with a depth and richness that reflects the buildings it helps to create and preserve.

Preserve Your Heritage with Expert Stonemasonry

At A F Jones Stonemasons, we understand the importance of preserving the past while embracing the future. With over 160 years of experience, our team combines traditional skills with cutting-edge technology to ensure your restoration projects honor history with precision and care. Whether you’re looking to restore a historic landmark or incorporate stonemasonry into your modern design, we are equipped to handle projects of all sizes. Visit our showroom in Oxfordshire, or make an enquiry today to see how we can bring your vision to life with the perfect blend of heritage craftsmanship and modern innovation.