Post Tension Stone Staircases

Post-tensioned staircases push stone to its limits.

High-strength steel tendons are threaded through carefully drilled treads and tensioned after installation, placing the stone into permanent compression.

The result is a free-standing stair in solid stone that appears to float, combining architectural ambition with a structural system that is both proven and precisely controlled.

STONE HELD IN PERFECT TENSION

Post-tensioning allows the staircase to support itself from within.

Rather than relying on embedment into a load-bearing wall, the stone and steel work together as a single, self-supporting structure.

This unlocks forms that would otherwise be difficult to achieve in stone – from slender straight flights to sweeping spirals in open atriums – with minimal visible structure and a continuous line in the space it occupies.

Process Details

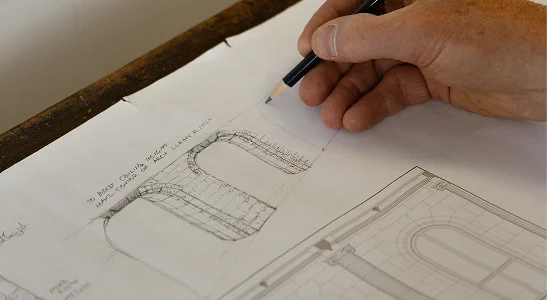

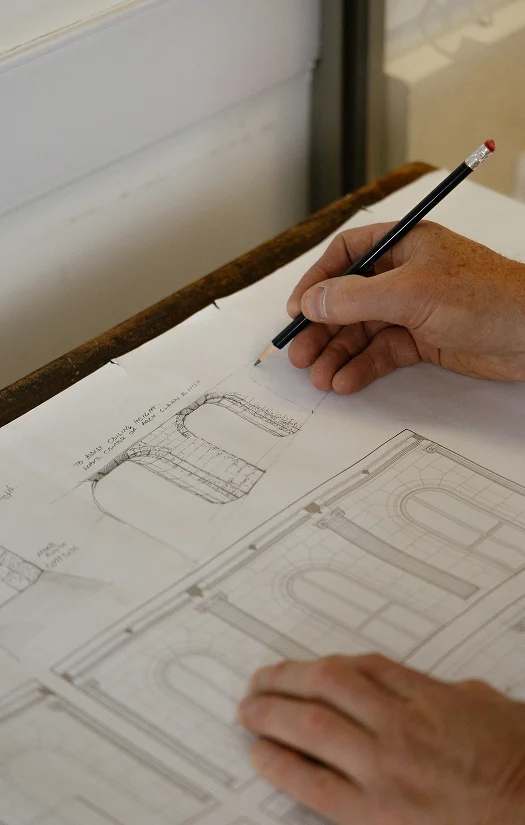

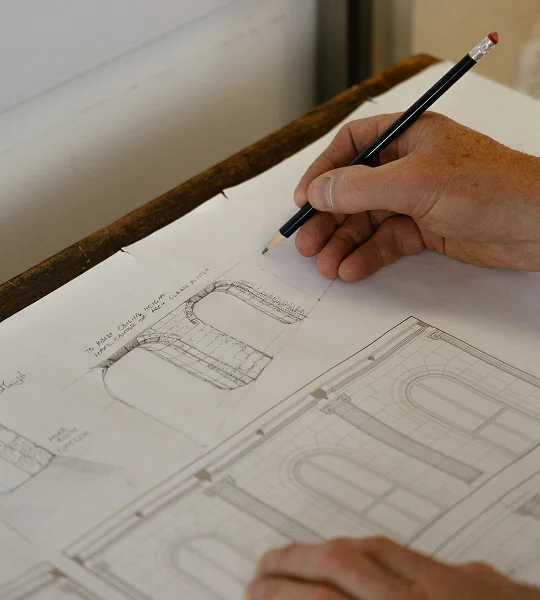

DESIGN

Our service includes the structural design of the stone assembly, including the connecting brackets where necessary, and also drawing the geometry in 3D.

FABRICATION

Using our state-of-the-art factory and machinery we can make the treads to any shape and detail you require.

INSTALLATION

With a bit of forethought and provision of temporary lifting beams, the installation process becomes a relatively smooth and simple process.

INSTALLATION

With a bit of forethought and provision of temporary lifting beams, the installation process becomes a relatively smooth and simple process.

Brief, Feasibility and Concepts

We begin by understanding the building, the desired geometry and how the stair will be used. At this stage we discuss whether a post-tensioned solution is appropriate and review plans and their constraints. Early modelling helps define tendon paths, interlocks and stressing zones, ensuring the concept is buildable before design progresses. Early conversations help align ambition, feasibility, budget and programme.

Stone Selection and Detailed Design

The choice of stone is critical. Dense limestones, granites and fine-grained materials are typically preferred for their strength and consistency. We provide guidance on suitable stones and lead the detailed design process, including 3D modelling, tendon geometry, anchorage zones, interlock details and bracketry.

Workshop Production and Trails

Fabrication takes place in our Oxfordshire workshops using advanced CNC cutting supported by hand finishing. Full-scale mock-ups or partial assemblies can be produced where beneficial, allowing teams to review the geometry and connection details before it's taken to site. This preparation removes uncertainty during a project and refines the design with real, physical insight.

Installation and Tensioning on Site

Installation is carried out by our specialist on-site teams, supported by temporary works until the structure is fully tensioned. We coordinate with specialists, manage tolerances and ensure the stair performs exactly as designed. Our familiarity with the sequencing and technical demands of these projects helps keep site progress smooth and predictable.

Quality, Compliance and Safety

Because post-tensioned stairs are structural elements, quality control and compliance are built into every stage. From load testing to inspection we ensure that the finished staircase meets engineering, safety and building control standards.

Aftercare and Ongoing Support

Once complete, we remain available for guidance on cleaning, protection and long-term care. Post-tensioned stairs are engineered for decades of performance, and thoughtful maintenance helps protect their strength and appearance.

ENGINEERING ELEGANCE IN STONE

Post-tensioned stone staircases offer a rare combination of structural innovation and sculptural presence.

It allows stone to span further, turn tighter and read more lightly than traditional approaches, while still meeting modern structural codes.

Our role is to hold all of this complexity on your behalf – from engineering checks and tendon geometry to fabrication, stressing and final finishing – so you gain the freedom to design with confidence, knowing the stair will perform as beautifully as it looks.

Sign up to our Newsletter

Stay up to date with the our latest projects,

events and news by joining our newsletter